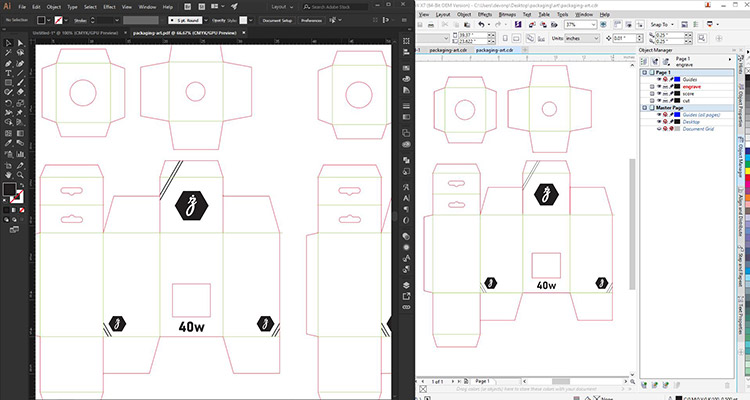

Download the graphics above and import it into your graphic software. Make adjustments as necessary.

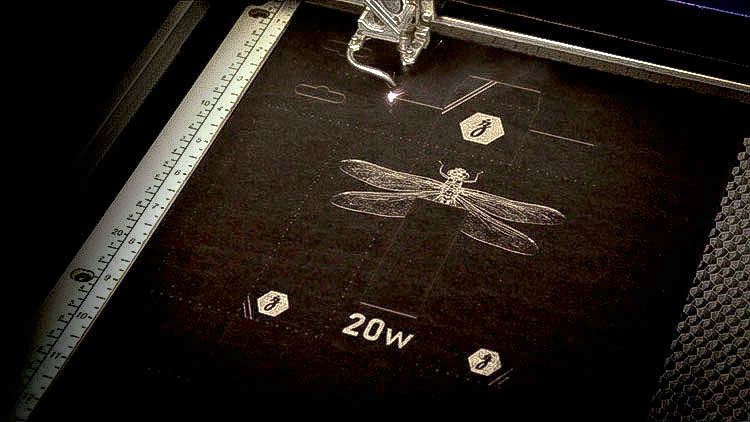

Send the job to the laser with the correct parameters for your machine wattage.

Pop the packaging out of the template, then fold and assemble the paper boxes. Use glue on the inside flap.