Laser Engraving & Cutting Leather

Laser machines for engraving leather and faux leather

Why Leather?

Leather is an exceptionally popular material to laser engrave and cut for a variety of reasons. Raw leather sheets and premade leather products are relatively affordable, extremely durable, and have a high perceived value, especially when they are personalized for a customer with a laser. Combining an Epilog Laser and this versatile substrate can open the door to many profitable applications and opportunities, from fashion accessories to promotional products and everything in between.

Types of Leather

The engraving results you achieve with your laser depend on the kind of leather you’re working with and how the laser beam reacts with it. There are four primary kinds of leather:

- Full-grain leather – highest quality

- Top grain leather – second highest quality

- Corrected grain (bottom/cut split leather) – also known as “genuine leather”

- Bonded leather – lowest quality, made up of leftovers of the hide

There are several options under the four primary types of leather including pigmented leather, veg-tanned leather, antique-grain leather, and many more.

Suede is another type of soft leather, and while not as durable as the types we mentioned above, it can also be laser engraved and cut.

Synthetic/Faux Leather

Synthetic or faux leather is another popular option for the laser, and is offered by many of the well-known laser-friendly substrate manufacturers. If your faux leather does not explicitly indicate it is laser-safe, we recommend checking with the manufacturer to ensure it does not contain Polyvinyl Chloride (PVC), which is harmful to you and your laser machine.

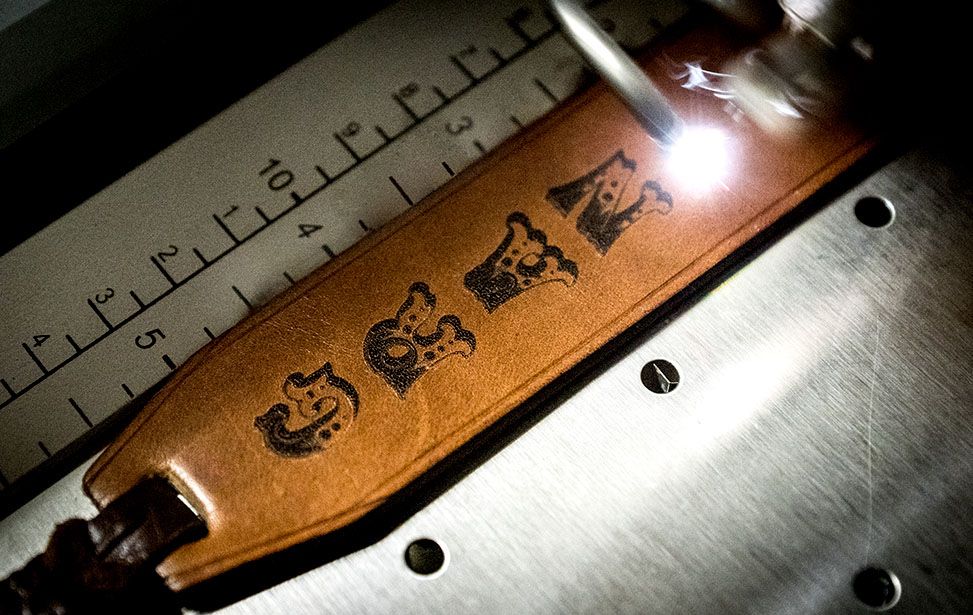

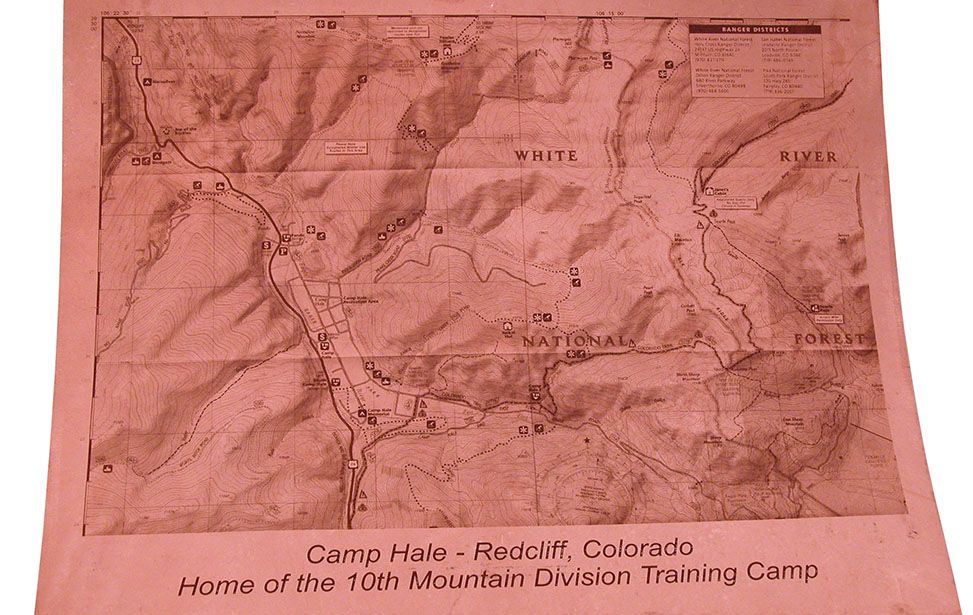

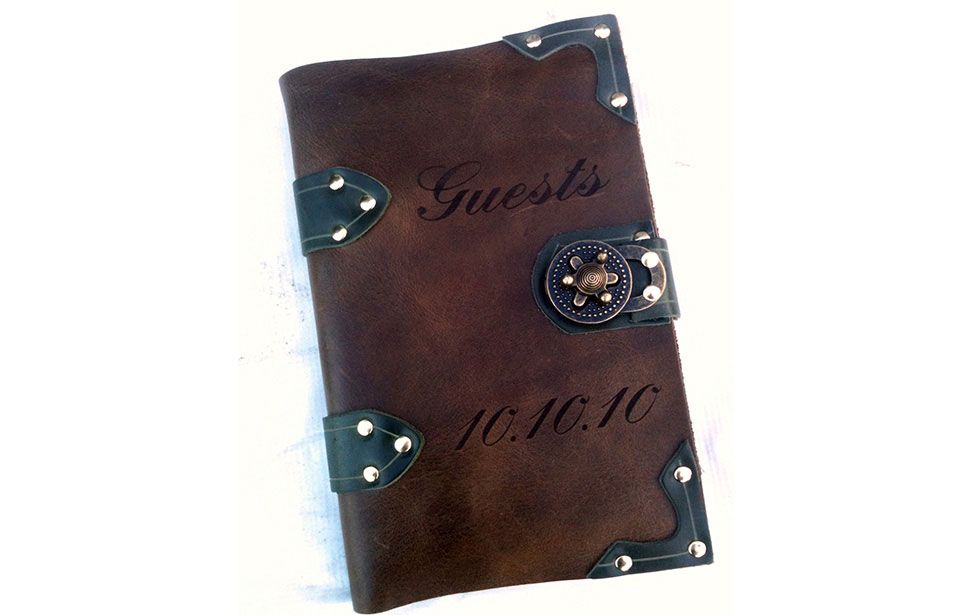

Laser Engraving Leather

The process of engraving or etching leather results in a debossed effect and, depending on the surface of the leather, produces a noticeable and clean contrast. Light-colored leathers produce significant color contrast, whereas engraving darker leathers results in a more subtle contrast. If you need a dynamic color contrast, go with a tan, beige, or light brown leather.

Your engraving results are mostly dependent on the type of leather used as well as your laser speed, power, and frequency settings. As with any material, we always recommend testing different parameters until you achieve your desired results.

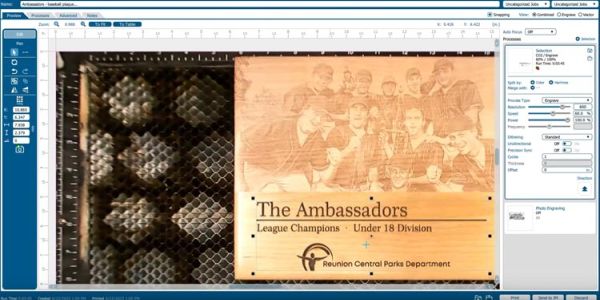

Laser Engraving a Children’s Leather Jacket

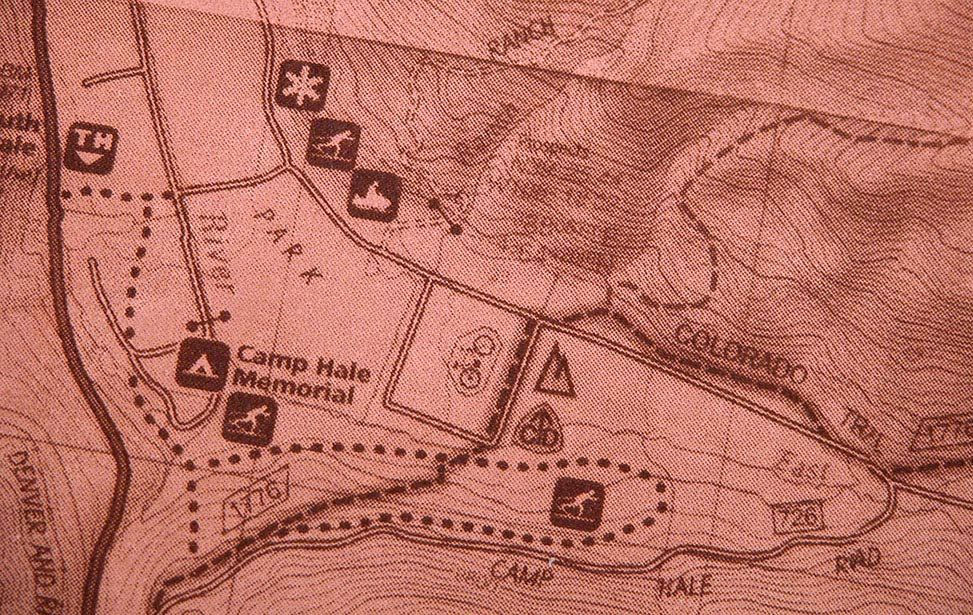

Laser Engraved Leather Map

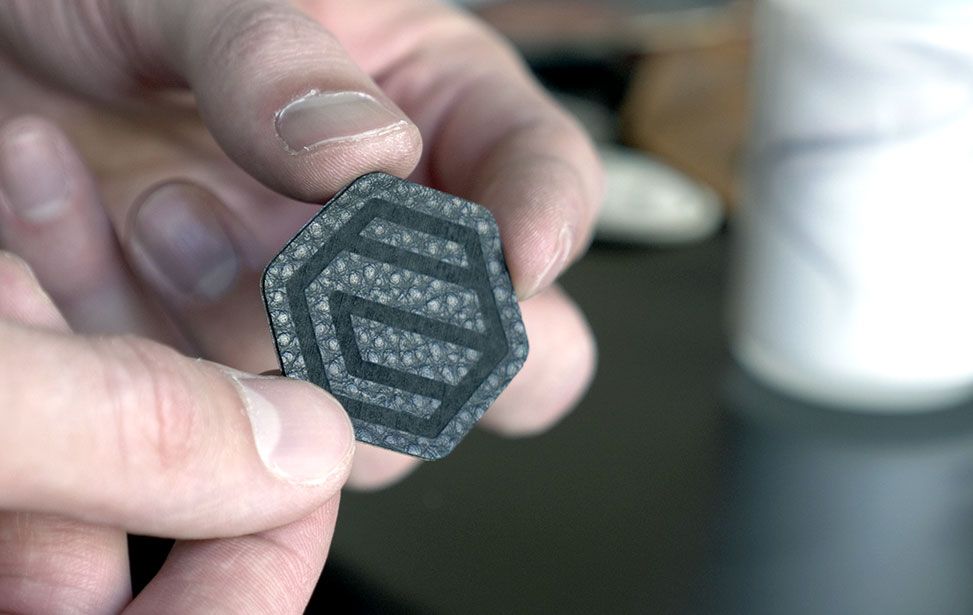

Laser Engraved Leather Hat Patch

Laser Cutting Leather

Depending on the wattage of your laser, you’ll be able to cut through leather anywhere between 1/16” and 1/4” in thickness, perhaps slightly thicker with two passes.

There are several benefits to using your laser to cut leather. First, the laser provides sealed cuts that won’t fray or otherwise deteriorate. Secondly, unlike manual leather cutting tools such as utility knives and rotary cutters, cutting leather with a laser is incredibly fast, precise, and perhaps most importantly, consistent. Additionally, cutting with the laser eliminates warping that can sometimes happen with hand tools.

When using the laser to cut leather, there is no part-to-part contact, which means there are no blades or costly parts to replace. Lastly, there’s no time wasted clamping down leather for processing. Simply insert the sheet into your laser bed and engrave or cut your desired pattern.

What kinds of leather products can you laser engrave/cut?

- Bookmarks

- Bracelets

- Briefcases & portfolios

- Coasters

- Guitar straps

- Hat patches

- Headbands

- Journals

- Keychains

- Necklaces

- Ornaments

- Pet collars

- Photographs

- Purses & handbags

- Shoes

- Sports memorabilia

- Wallets

- …and so much more!

Engraving is Easy!

Print to your laser from any graphics software

Artwork Setup

Design in your favorite software

Material Settings

Assign speed and power by material

Start Engraving!

Send the job to the laser and press go!

Looking for a little laser inspiration?

You may also like…

Which machines are best for laser engraving leather?

-

Fusion Edge 12

Business SeriesWork Area24″ x 12″

(610 x 305mm)TypeCO2, Fiber

WattageCO2: 50-60

Fiber: 30Our compact laser system available in several wattage configurations and features up to 120 IPS/3.05 m/s engraving speeds. Also available with a fiber laser source. -

Fusion Edge 24

Business SeriesWork Area24″ x 24″

(610 x 610mm)TypeCO2

WattageCO2: 50-60

A mid-size system that includes Epilog’s IRIS Camera System. -

Fusion Edge 36

Business SeriesWork Area36″ x 24″

(914 x 610mm)TypeCO2

WattageCO2: 60-100

The largest system in the Fusion Edge Series, the Edge 36 offers a 36” x 24” (914 x 610 mm) engraving table and comes in a 60, 80, or 100 watt CO2 configuration. The Edge 36 features 120 IPS/3.05 m/s engraving speeds, and features built-in Ethernet, USB, and Wireless options for networking your laser. -

Fusion Pro 24

Industrial SeriesWork Area24″ x 24″

(610 x 610mm)TypeCO2, Fiber, Dual

WattageCO2: 60-100

Fiber: 30The smallest in our industrial Fusion Pro Laser Series, the Pro 24 is available in 60, 80, or 100 watts and can be configured as a dual-source system with both CO2 and fiber laser capabilities. -

Fusion Pro 36

Industrial SeriesWork Area36″ x 24″

(914 x 610mm)TypeCO2, Dual

WattageCO2: 60-200

Fiber: 30-60Like all systems in the Fusion Pro Laser Series, the Pro 36 includes Epilog’s IRIS Camera System, along with engraving speeds up to 165 inches per second (4.2 m/s). -

Fusion Pro 48

Industrial SeriesWork Area48″ x 36″

(1219 x 914mm)TypeCO2, Dual

WattageCO2: 80-200

Fiber: 60The largest of the Fusion Pros, this industrial system is available in 80, 100, 120, and 200 watt configurations, as a dual-source system, and can be networked via built-in Ethernet, USB or wirelessly.