Laser Engraving and Engraver Machines

Laser engrave graphics, text, and photos on a variety of materials

Epilog CO2 Laser Engravers:

A World of Engraving Possibilities

Epilog laser engravers and engraving machines, such as those in the Fusion Maker, Edge, and Pro series, offer a world of possibilities. More versatile than router engravers or milling machines, and faster than diode and glass tube lasers, Epilog’s CO2 laser engravers can quickly and easily create personalized wood products, engrave tumblers and wine glasses, etch on stone or plastic, mark coated metal plates, print on fabric and leather, and so much more!

Laser Engraving Projects for Personalized Gifts, Home Decor, and the Holidays

Which materials can you laser engrave?

Engrave and mark a wide array of materials

- Wood

- Extruded or Cast Acrylic

- Fabric

- Stone, Marble, and Granite

- Leather

- Anodized Aluminum

- Paper and Cardboard

- Stamp Rubber

- And Many More!

- See the Full Materials List

Request Free Samples and Information

"*" indicates required fields

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Thanks to Epilog’s easy to use design, engraving precision, repeatability, and fast speeds, these laser engravers provide anyone, from beginners to seasoned entrepreneurs, the ability to make their ideas and products in minutes. Designed to be as easy to use as an office printer, a CO2 or fiber laser engraver allows you to create designs with any graphic design software and “print it” directly on any product with your laser machine.

Laser Engraving with an Epilog is Easy!

Print from your favorite design software

Epilog’s laser engraving machines are incredibly easy to use, even for beginners. The process is similar to using an office printer. Just follow these simple steps: start with your design and print, choose your material, send it to the laser and push GO to start engraving!

You can design your way and use any graphic design software, such as Adobe Illustrator, CorelDRAW, Canva, Inkscape, and others.

Design & Print

Print from your favorite software

Select your material

Choose your material to set engraving and cutting speed and power

Laser Engrave It!

Press Go at the laser and engrave and cut your project!

Laser Engraver Machines: Quick Guide Information

-

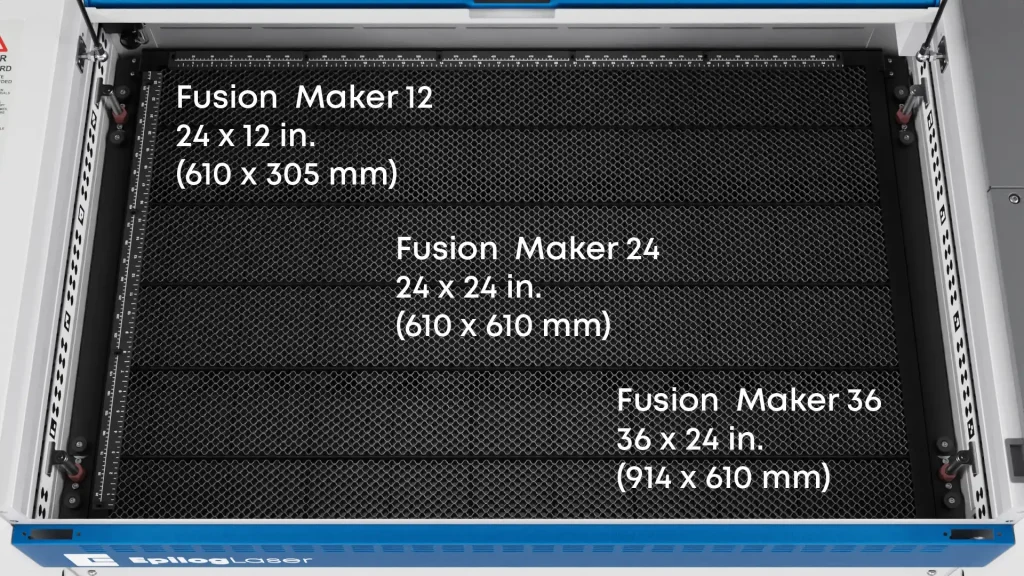

The Fusion Maker Starter Series is a great option for those who are new to laser engraving and cutting. Our line of affordable, easy-to-use laser machines is perfect for businesses, schools, and hobbyists. The Maker Series includes three laser machines: the Fusion Maker 12, 24, and 36. All three machines are equipped with Epilog’s IRIS™ Camera Positioning System, providing a real-time view of the engraving table for accurately positioning artwork on your laser projects. The Starter Series also includes easy-to-use and learn Epilog Dashboard software.

Fusion Maker Work Table Cutting Grid Sizes

Work Area: Up to 36″ x 24″ (914 x 610 mm) Material Thickness: Up to 10″ (254 mm) Laser Tube Types: Air-cooled, metal/ceramic tube. Epilog Laser Manufactured. Laser Tube: CO2: Up to 50 watts Engraving Speed: 60 IPS (1.5m/s) Maximum IRIS™ Cameras: 1 or 2 overhead -

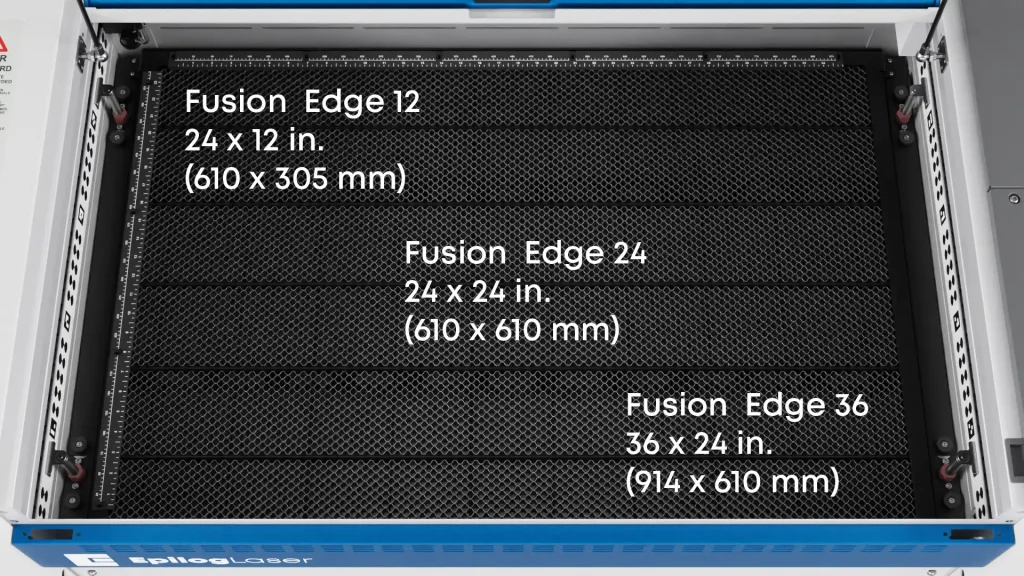

Featuring up to 120 IPS (3.05 m/s) engraving speeds, 5g acceleration, and a variety of wattage configurations, the Fusion Edge Laser Series from Epilog can help you boost your productivity and expand your product offerings. Comprised of the Fusion Edge 12, 24, and 36, all the machines in the Edge Series feature Epilog’s revolutionary IRIS™ Camera Positioning System that gives laser operators a real-time image of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items.

Fusion Edge Work Table Cutting Grid Sizes

Work Area: Up to 36″ x 24″ (914 x 610 mm) Material Thickness: Up to 10″ (254 mm) Laser Tube Types: CO2 or Fiber Laser Tube: CO2: Up to 60 watts

Fiber: 30 watts (Edge 12)Engraving Speed: 120 IPS (3.05m/s) Maximum IRIS™ Cameras: 1 or 2 overhead -

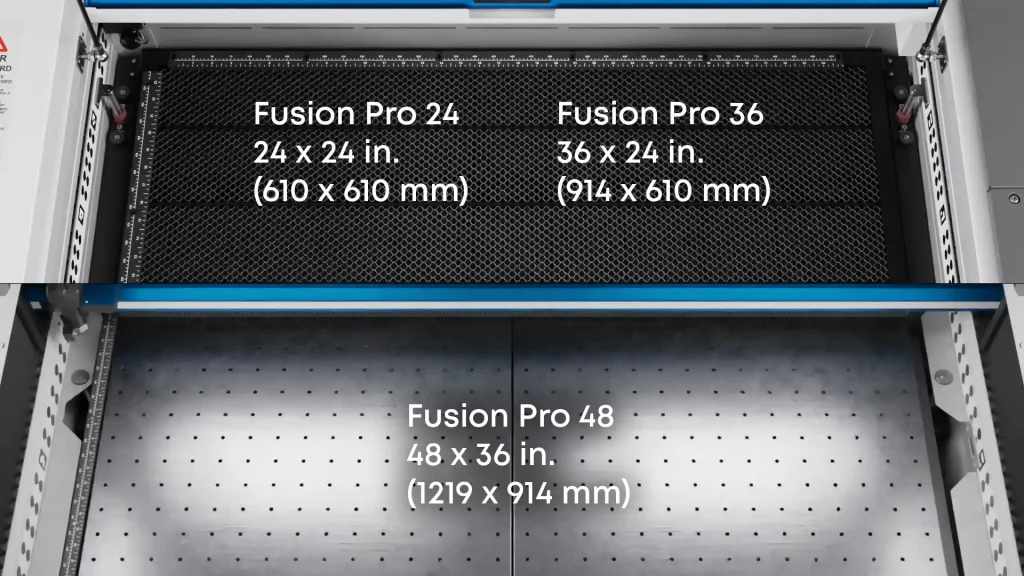

Fusion Pro Industrial Series

Featuring up to 165 IPS (4.2 m/s) engraving speeds, 5g acceleration, and a variety of wattage configurations, the easy-to-use Fusion Pro Laser Series from Epilog can help you improve your business laser workflow productivity and expand your customer base with more product offerings.

Comprised of the Fusion Pro 24, 36, and 48, all the machines in the Pro Series feature Epilog’s revolutionary IRIS™ Camera System with Positioning and Registration cutting features, gives laser operators a live-preview of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items.

Work Area: Up to 48″ x 36″

(1219 x 914 mm)Material Thickness: Up to 12.25″ (311 mm) Laser Tube Types: CO2, Fiber, or Dual Source Laser Tube: CO2: Up to 120 watts

Fiber: Up to 50 wattsEngraving Speed: 165 IPS (4.2 m/s) Maximum IRIS™ Cameras: 2 overhead + registration

LASER APPLICATION GALLERY: Examples of Laser Engraving Projects

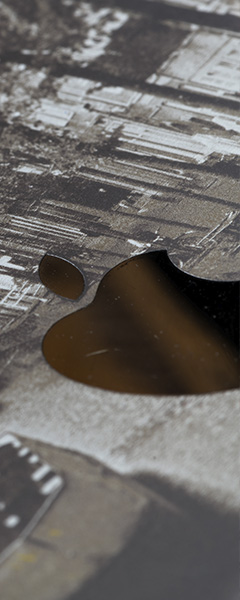

-

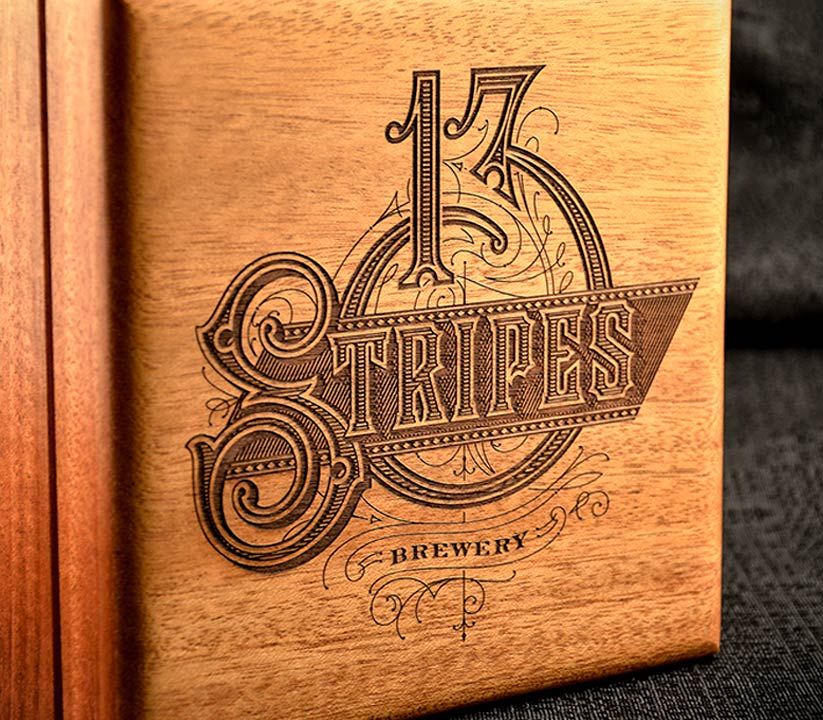

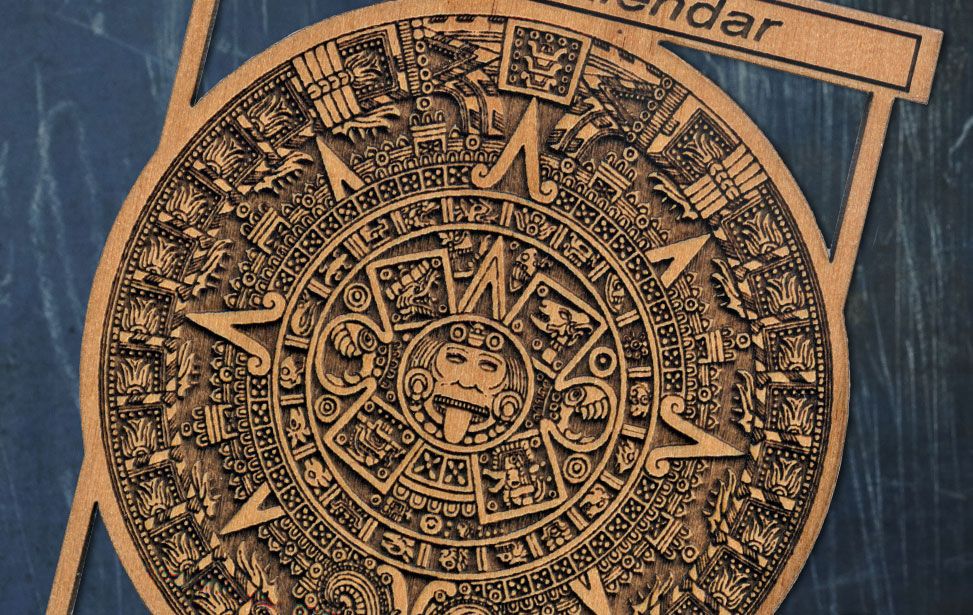

Wood

HouseAmazing Detail!

Wedding Photos

Amazing Detail!

Cutting Board

Amazing Detail!

Wine Phone Booth

Amazing Detail!

Ornate Detail

Amazing Detail!

Rolling Pins

Amazing Detail! -

Layered Sign

Amazing Detail!

Acrylic Sign

Amazing Detail!

Numbered Sign

Amazing Detail!

Acrylic LED Sign

Amazing Detail!

Acrylic Employee Sign

Amazing Detail! -

Engraving iPad

Amazing Detail!

Water Bottles

Amazing Detail! -

Wine Bottles

Amazing Detail!

Shot Glasses

Amazing Detail!

Pint Glasses

Amazing Detail! -

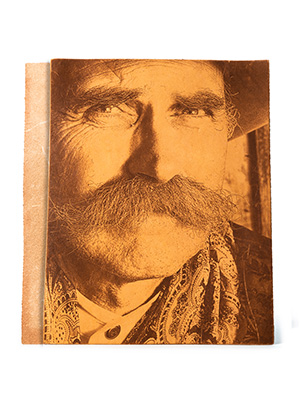

Photo on Leather

Amazing Detail!

Engraving on Hats

Amazing Detail!

Leather Journal

Amazing Detail!

Pet Accessories

Amazing Detail!

Leather Pillows

Amazing Detail! -

3D Cardboard Rhino

Amazing Detail!

Paper Monsters

Amazing Detail!

Layered Carboard Wave

Amazing Detail!

Laser Engraved Packaging

Amazing Detail!

Amazing Detail!

Amazing Detail! -

Material Engrave Cut Acrylic Anodized Aluminum Ceramic Cloth Coated Metals Corian Cork Delrin Fabric Fiberglass Material Engrave Cut Glass Leather Marble Stainless Steel * Brass * Matte Board Melamine Mother of Pearl Mylar Painted Metals Material Engrave Cut Paper Plastic Pressboard Rubber Tile Wood Wood Veneer Titanium * Bare Metals * * CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page.

Do you have a material you would like us to test? Our Applications Team would be happy to assist you.

| Material | Engrave | Cut |

|---|---|---|

| Acrylic | ||

| Anodized Aluminum | ||

| Ceramic | ||

| Cloth | ||

| Coated Metals | ||

| Corian | ||

| Cork | ||

| Delrin | ||

| Fabric | ||

| Fiberglass |

| Material | Engrave | Cut |

|---|---|---|

| Glass | ||

| Leather | ||

| Marble | ||

| Stainless Steel | * | |

| Brass | * | |

| Matte Board | ||

| Melamine | ||

| Mother of Pearl | ||

| Mylar | ||

| Painted Metals |

| Material | Engrave | Cut |

|---|---|---|

| Paper | ||

| Plastic | ||

| Pressboard | ||

| Rubber | ||

| Tile | ||

| Wood | ||

| Wood Veneer | ||

| Titanium | * | |

| Bare Metals | * | |

* CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page.

Do you have a material you would like us to test? Our Applications Team would be happy to assist you.

What are the best uses for an Epilog laser engraver?

GIFT PERSONALIZATION

INDUSTRIAL MARKING

ARTS AND CRAFTS

Artists and crafters can use laser engravers to create intricate designs and patterns on a variety of materials, including wood, acrylic, leather, fabric and more. With and Epilog engraver the laser customization possibilities are endless.

SIGN & DISPLAY MAKING

Laser cutters and engravers can be used to create indoor and outdoor signage, name plates, and corporate logo signs. An Epilog is the perfect tool for creating exceptionally details shapes for POS displays, pop-up exhibits, and illuminated advertising signs.

RAPID PROTOTYPING

Often used in product development, laser cutters and engravers are utalized to create prototypes of new products and reduce lead times. An Epilog can cut and engrave materials with speed and precision, allowing designers and engineers to test and refine their ideas.

ARCHITECTURAL MODELS

Architects and model makers use laser engravers to create detailed models of buildings and other structures for large contruction projects. The technique of using lasers gives many architect firms and students the ability to speed up the model making process and design with modern solutions.

EDUCATION IN UNIVERSITIES & STEM PROGRAMS

Laser cutters and engravers are used in schools and universities to teach students about design, engineering, and subtractive manufacturing processes. Students can learn to create their own designs and bring them to life with a laser engraver.

The Benefits of Owning an Epilog Laser Engraver

Laser Engraving and Customization

Laser Cut Your Designs

Laser Touch Screen

Personalize Any Product

Dual Laser Source Options Available

IRIS™ Camera Positioning System

Epilog’s Additional Standout Features

LASER ENGRAVE A VARIETY OF MATERIALS

WE’LL HELP YOUR LASER BUSINESS

Not sure what you want to create? Epilog provides resources to inspire with our Sample Club, Youtube, Instagram, and Facebook Fans group.

DESIGNED FOR EASE OF USE

The laser connects to your computer like an inkjet printer through Wireless, USB or Ethernet options. Use the design software of your choice to start laser engraving your project!

AFFORDABLE DESIGN

A laser machine from Epilog is an excellent choice for your first laser system. The Fusion Maker combines top-notch industrial components and the highest-quality engraving in an affordable desktop package.

SAFE TO OPERATE – Class 2 Laser

The laser’s interlocked metal enclosure carries a class 2 safety rating, allowing for safe use in any student lab, workshop, home, or office.