Custom Gun Rails, Inc.

Enterprise uses laser technology to create one-of-a-kind equipment

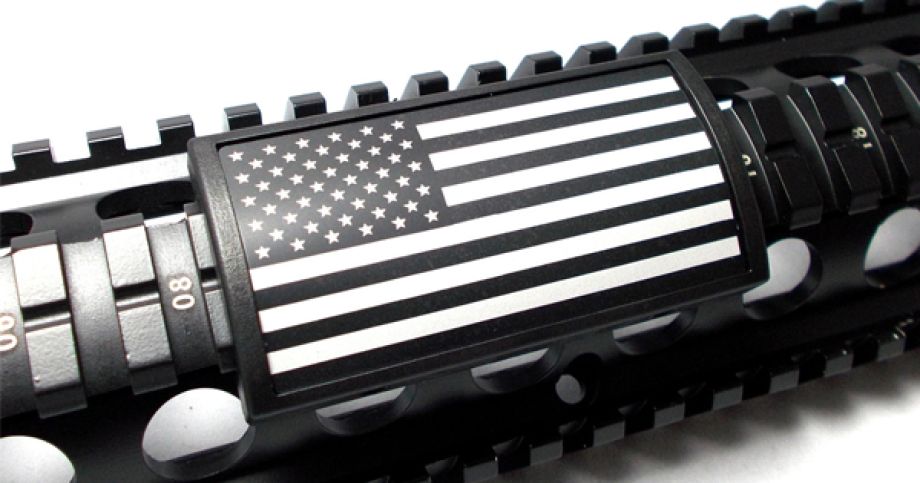

In business since 2011, Custom Gun Rails specializes in producing rail covers that are able to mount on any Picatinny rail system, which are often found on rifles and other tactical gear. Customers can select from hundreds of pre-designed covers, or they can choose to have their own graphics laser engraved with CGR’s 40-watt Epilog Mini 18.

“We were complete laser novices before we got our machine,” said Jennifer Limvorratre, Director of Operations at CGR. “All we knew was that we needed something that was fast, precise, and easy to use.”

Upon the recommendation of a friend in the industry, Angel Mendez, President and CEO of CGR, and Jennifer decided to check out Epilog Laser.

“The laser is exceptionally easy to run and we do nearly everything with this machine,” Jennifer said. “In addition to the rails, we do a lot of anodized aluminum custom dog tags. In fact, we actually brought the laser into our daughter’s school classroom and lasered tags for all of her classmates – the kids were fascinated by the laser and we loved providing such an interactive and educational experience for them!”

Jennifer told us that while CGR does work with a lot of anodized aluminum, they also work with a myriad of other materials.

“Not only do we engrave a lot of anodized aluminum, but we also cut all kinds of materials including plastics, rubber, wood, and much more. We do a lot of the same type of projects over and over again, and the Epilog has also made it super easy to create jigs that allow for more seamless production.”

“Utilizing the laser to etch/engrave rail covers allows us to take our customization services to a higher level,” Jennifer told us. “Customers can have a message or express themselves however they’d like without permanently altering their gear.”

“Our Epilog Laser system has revolutionized the way we approach manufacturing,” Jennifer said. “We can go from concept to production in no time at all.”