Laser Tips & Insights

Epilog’s Laser Engraving & Cutting Blog

Choosing the Best Laser Engraver for Wood Engraving Projects

Photographs are a highly popular choice for laser engraving.

Education: How to Pick the Best Laser Machine for Schools

Find the best laser engraving and cutting machine for your school to enhance STEM learning, creativity, and hands-on education. Discover how lasers benefit classrooms, fundraising, and school projects.

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Discover the essential speed and power settings for successful laser engraving on wood, acrylic, glass, and plastic. This guide offers helpful tips and techniques for achieving flawless results, no matter the material.

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

Laser engraving on glass and crystal creates stunning, personalized designs, but working with this delicate material requires precision.

How CO2 Laser Machines Can Increase Profits for Your Business

Learn how CO2 laser engraving can add value to products and provide unique gifting solutions.

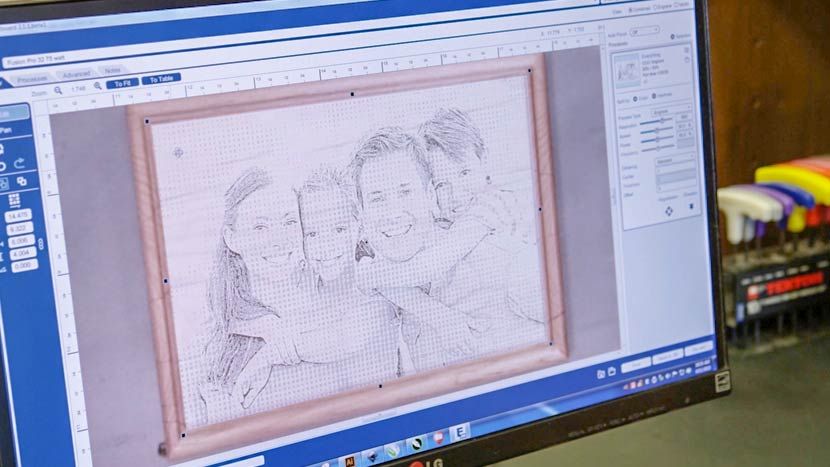

Laser Engraving Photos: Tips for Beginners

Photographs are a highly popular choice for laser engraving.

Top 10 Frequently Asked Laser Questions from Epilog Fans

Our Fans Asked, and we Answered – Here’s a look at 10 of the most frequently asked questions our fans ask, along with answers from our experts!

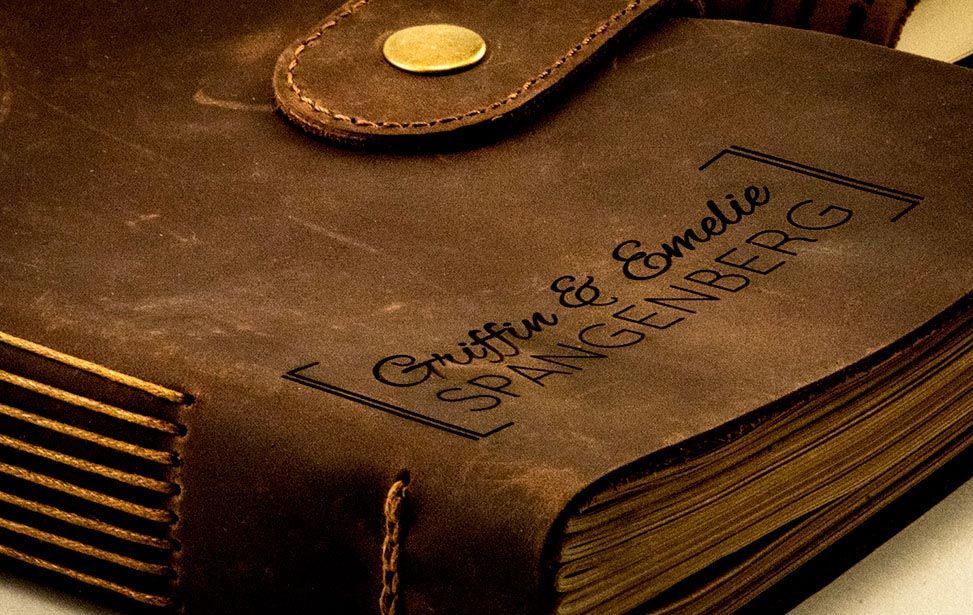

Laser Engraving Leather Debossing Stamps with MDF and Acrylic

A fun way to use your laser machine to achieve a unique look on leather.

Glass (DC) vs. Metal Ceramic (RF) CO2 Laser Tubes

Why are Epilog Laser machines built with air-cooled metal laser tubes?

5 Holiday Gifts You Can Make with a Laser

Impress your friends and family this holiday season with these easy-to-make projects.