High-Performance RF CO2 Laser Tubes, Created in Golden, CO

Experience the Epilog difference—where quality begins at the source.

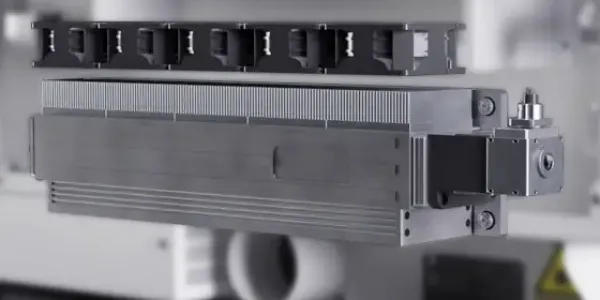

Epilog’s RF Laser Tubes

Built In-House at the Base of the Rocky Mountains

At Epilog, we engineer performance from the inside out. For over 20 years, Epilog has designed, tested, and built our own metal/ceramic RF laser tubes in-house at our Golden, Colorado headquarters by the same team that creates our laser systems. This integrated approach allows us to maintain complete control over quality, innovation, performance, and reliability.

Why don’t we source our laser tubes from third parties?

Why don’t we source our laser tubes from third parties?

The majority of laser machine manufacturers rely on third-parties for their laser tubes. Why don’t we?

Because unlike generic or third-party options, designing and building our custom-engineered tubes in-house allows us to use the most refined techniques to ensure they are tuned specifically for engraving and cutting applications, maximizing resolution, speed, and reliability.

Making our own tubes in-house offers several benefits to our customers.

Benefits

- Lower cost to recharge & replace

- Quicker turnaround to replace or repair a tube, should the need arise

- Heightened quality control

- Meeting the specific needs of our customers’ applications

- Ensuring each tube meets the Epilog Standard

– we are not dependent on third parties for the quality of our product

Premium Laser Tubes You Can Trust

CO₂ laser tubes are highly sensitive to contamination, so every step in the production process is critical. That’s why in our near 44,000 square foot production facility we have a state-of-the-art clean room to ensure optimum performance and the longest lifespan. Our meticulous manufacturing process ensures consistent beam quality, long lifespan, and top-tier engraving and cutting performance—even under the most demanding workloads.

When you choose Epilog, you’re getting the highest-performing RF laser tube on the market, purpose-built for precision, speed, and long-term durability. It’s how we deliver the industry’s best engraving results—every time.

What Makes Epilog Laser Tubes Different?

Our RF laser tubes stand out in the market because they are built for exceptional durability, beam quality, and long-term performance—perfect for both high-volume production and precision engraving or cutting applications. Key features include:

- Air-cooled tubes instead of water-based cooling systems, which simplifies operation, reduces maintenance, and eliminates the need for water chillers

- RF-excited metal/ceramic construction for superior thermal stability

- Excellent beam quality for fine detail and clean cuts

- High-speed pulsing for sharp and fast engraving

- Refined gas fill process for excellent gas lifetime

- Integrated collimator for a tightly focused, clean beam

- Fully sealed construction providing ruggedness and durability even in demanding environments

- Stable power output, leading to consistent results across projects

- Reliable engraving consistency, crucial for high-speed, high-resolution work

Built for Long-Term Performance

This isn’t just about power—it’s about precision. Whether you’re engraving intricate graphics or cutting thick materials, our RF laser tubes deliver the clarity, consistency, and reliability professionals demand. Investing in a high-quality laser tube translates to better performance, reduced downtime, and longer-lasting equipment.

We hold several patents on our core laser tube innovations. These patents are a testament to our role as a technology leader, not just a product assembler. We invest heavily in ongoing laser research and development—not only to improve current products, but also to push the boundaries of what’s possible in laser engraving.

Extensively Tested

Rechargeable

Rechargeable, extending system life and reducing waste while saving you money when the tube does eventually need to be replaced.

Laser optics can be replaced, and the tube itself can be reprocessed, making factory service both straightforward and affordable

Engineered to Endure

Laser Tube Comparison

Epilog RF laser tubes are serviceable, making the tube replacement costs over 10 years the most affordable option available on the market, even compared to glass laser tubes.

| Glass Laser Tube – 40W (water cooled) | Import RF Laser Tube – 30W (air-cooled) | Epilog Laser Tube – 30W (air-cooled) | |

| Use Case: | Hobby | Prosumer | Business |

| Tube Lifetime (avg)*: | 1 year | 3 years | 6 years** |

| Replacement cost: | ~$400 | ~$2,400 | ~$2,100*** |

| Number of replacements in 10 years: | 10 | 3 | 1 |

| Total Replacement Costs for 10 years: | $4,000 | $7,200 | $2,100 |

- * Tube lifetime averages may vary.

- ** Over 90% of our 30W laser tubes are still in the field after 6 years without needing to be recharged, meaning you don’t have to worry about downtime or replacement costs.

- *** We charge a CORE charge and reimburse you when you send us your old laser tube back, which is why our replacement cost is relatively low.

Created at the Base of the Rockies. Trusted Around the World.

From our roots in Golden, Colorado, Epilog Laser has grown into a name recognized across the globe. But we’ve never strayed from what matters: creating top-quality laser systems right here at home. By developing our systems and key components under one roof, we continue to deliver the performance, reliability, and support our customers have come to expect. The laser tube is the heart and soul of your laser machine – it’s what allows you to create intricate engravings, clean cuts, and a high-quality finished product. When your livelihood depends on consistent results, you can depend on Epilog.

Standard Machine Features:

IRIS™ Camera Positioning System