Laser Engraving & Marking Firearms

Customize firearms at the touch of a button

Customizing and Marking Firearms with Lasers

Epilog’s laser engraving and marking machines are used in countless industries around the world. One of the most popular is engraving and marking firearms and various gun accessories. Laser engraving and cutting machines are an ideal choice for firearm and firearm manufacturers for many reasons.

Durable, Detailed, & Personalized

-

Traceability and Identification:

Laser engraving and etching allows for clear and permanent engraving of serial numbers, manufacturer information, and other identifiers on firearms. This helps police and authorities track ownership and history.

-

Durability:

Laser marking is highly resistant to wear and corrosion, making it more durable than other forms of marking. This ensures that the information remains legible and intact over the life of the firearm, even with heavy use or exposure to harsh conditions.

-

Precision:

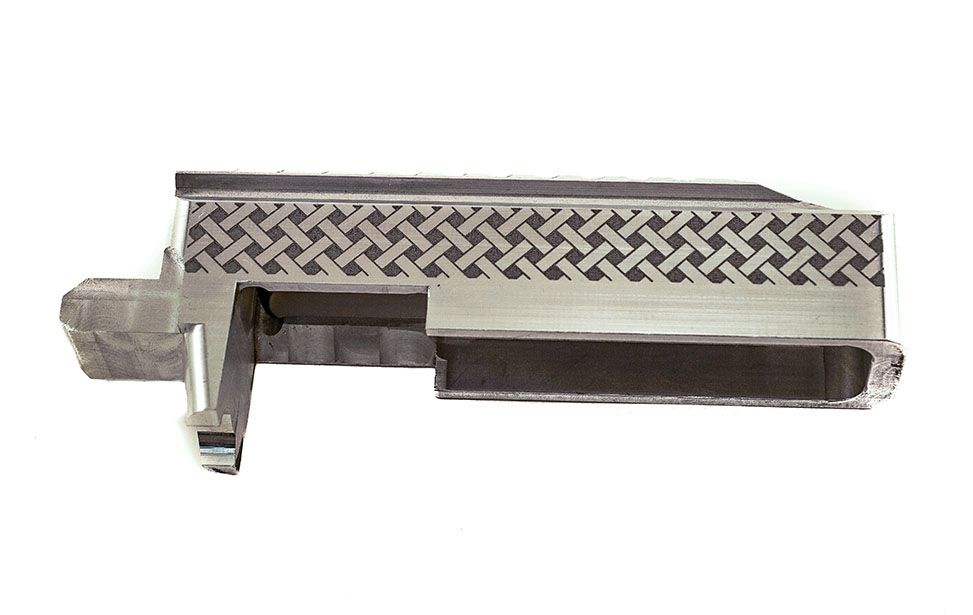

Laser marking is very precise and can create detailed designs that are hard to make with other methods. This allows for more detailed information and complex designs, improving the quality and readability of the markings.

-

Customization:

Gun owners often want their pieces to stand out. Offering laser engraving services can personalize firearms with unique designs or engravings, increasing their appeal and value.

Customization & Personalization

Custom Engravings: Allows for personalized messages, designs, or artwork, catering to customer preferences for unique, customized firearms.

Personalized Gifts:Engraving special dates, names, or insignias for commemorative or gift purposes.

Instructional & Safety Information

Safety Warnings: Permanent markings for safety warnings and operational instructions that remain legible even after extensive use.

Maintenance Instructions: You can mark information on proper care and maintenance directly on the firearm for user reference.

Durability & Legibility

Wear-Resistant Markings: Laser markings are exceptionally strong against wear and rust. This keeps important information clear for the life of the firearm.

High Contrast: Produces clear, high-contrast marks that are easily readable and aesthetically pleasing.

Security Features

Anti-Counterfeiting Measures: Laser marking can use detailed patterns or hidden codes. These help stop fake products and confirm the firearm’s authenticity.

Traceability: Enhances the traceability of firearms through embedded codes that can be scanned and identified if needed.

Serial Numbers & Identification

Unique Identification: Laser marking provides a durable and precise way to etch unique serial numbers on firearms, which is crucial for tracking and compliance with regulations.

Regulatory Compliance: Ensures firearms meet legal requirements for identification and traceability, including the markings required by law enforcement and regulatory agencies.

Branding & Logos

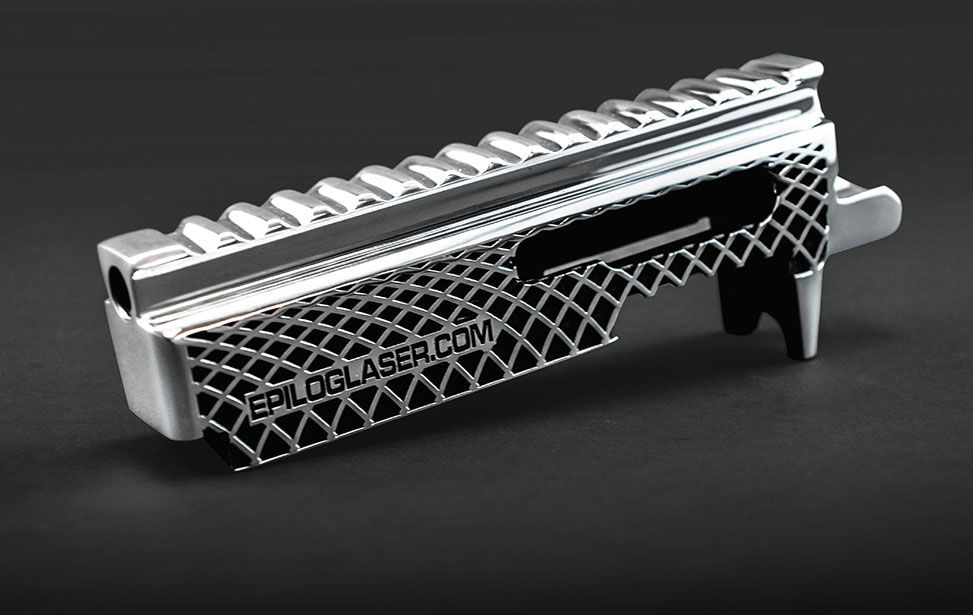

Company Logos: Manufacturers use laser marking to engrave their logos and brand names on firearms. This gives their products a professional and consistent look.

Model Information: This includes model numbers, calibers, and other details. These help users and service technicians identify and manage different firearms.

Component Marking

Part Identification: Marking components with identification codes or batch numbers to facilitate assembly and maintenance.

Inspection and Quality Control: Help monitor parts during production and assembly. This process supports quality control and makes sure parts fit together well.

Efficiency & Flexibility

Rapid Production: Laser marking systems can operate quickly and efficiently, which is beneficial for high-volume production environments.

Flexibility: Easily adapts to various materials and shapes, allowing for marking on diverse firearm components, from barrels to receivers.

Types of Laser Machines for Engraving Guns

Firearms are typically marked with three types of laser machines: Galvo, Flatbed Fiber, and Flatbed CO2. Each can produce lasting marks on all types of guns. The laser you choose is dependent on the size of your product and the type of mark you want to achieve.

Fusion Galvo

A galvo laser is fast, precise, and versatile. This makes it a great choice for marking firearms. It provides clear, durable, and high-quality engravings. These engravings meet industry standards and regulatory requirements.

Using a galvo laser for marking firearms offers several advantages that make it a preferred choice for this application:

Advantages of Galvo Lasers:

Speed and Efficiency: Galvo lasers are known for their high marking speed due to their rapid scanning capabilities. This efficiency is particularly valuable in a production environment where time is a critical factor.

Precision and Accuracy: Galvo systems use galvanometer-driven mirrors to direct the laser beam with high precision. This allows for detailed and accurate markings, which is essential for the clear and permanent engraving of serial numbers and other identifiers on firearms.

High-Quality Marking: Galvo lasers make clear and sharp markings. They provide a steady depth and contrast. This quality is important for compliance with legal requirements and ensures that the markings remain legible over the life of the firearm.

Versatility: Galvo lasers can mark a variety of materials commonly used in firearms, including metals like steel, aluminum, and titanium. They can handle different surface finishes and textures, which is beneficial for the diverse range of firearm components.

Minimal Heat Affected Zone: Galvo lasers create very little heat. This lowers the chance of changing the firearm’s material or causing thermal damage. This is crucial for maintaining the integrity and safety of the firearm.

Low Maintenance: Galvo laser systems generally require less maintenance compared to other laser types. Their solid-state design and fewer moving parts contribute to reliability and reduced operational costs.

Flexibility in Design: Galvo lasers can easily handle complex and intricate designs, allowing for detailed customization and additional features such as logos or barcodes. This flexibility enhances the aesthetic and functional aspects of the firearm marking.

Consistency: The precision and automation capabilities of galvo lasers ensure consistent results across large production runs. This consistency is vital for meeting regulatory standards and maintaining product quality.

FLAT BED

Using a flatbed fiber laser to mark firearms is another viable option that offers specific advantages and considerations.

Advantages of Flatbed Fiber Lasers:

Size: Flatbed fiber lasers have a big working area, good for marking large or irregular firearm parts. They are bigger than galvo systems, making them useful for different shapes and sizes. This is particularly useful for components that may not fit easily in a smaller galvo system.

Precision: Fiber lasers provide high precision and are capable of producing sharp, detailed markings. This is crucial for engraving serial numbers, manufacturer information, and other identifiers clearly and permanently.

Versatility: Flatbed fiber lasers can mark a wide range of materials, including metals commonly used in firearms such as steel, aluminum, and titanium. They are versatile in handling different surface finishes and types.

Ease of Use: Epilog’s flatbed fiber lasers are very user friendly, featuring with intuitive software and controls. Couple that with our revolutionary IRIS Camera System and you’ll be setting up and running engraving jobs in no time.

Advantages of Flatbed CO2 Lasers:

High Precision and Detail: Flatbed CO2 lasers can engrave intricate patterns, serial numbers, and logos with exceptional accuracy. This precision is ideal for meeting firearm industry standards for traceability and compliance.

Permanent and Durable Markings: CO2 lasers create marks that are permanent, wear-resistant, and corrosion-proof, ensuring that critical information like serial numbers remains legible—even under harsh conditions or heavy use.

Non-Contact Process: Since CO2 lasers use non-contact engraving, there’s no physical pressure on the firearm, minimizing risk of warping or surface damage—especially important for delicate components or finishes.

Versatility in Materials: While metals are often marked using fiber lasers, Flatbed CO₂ lasers can be ideal for polymer and composite parts commonly found in modern firearms (e.g. pistol frames, grips, accessories).

Things to Consider when Choosing between

a Galvo and Flatbed Laser Machine

Speed

While flatbed fiber lasers are efficient, they may not match the speed of galvo lasers in high-volume production scenarios. For very high-speed applications, galvo lasers might still have an edge.

Space Requirements

Flatbed fiber lasers usually require more space than galvo systems due to their larger working area. Ensure that you have adequate space in your facility to accommodate the equipment.

Maintenance

While fiber lasers are generally low-maintenance, flatbed systems might have different maintenance needs compared to galvo systems. Regular upkeep is important to ensure consistent performance and quality.

Using Epilog Laser machines

to meet ATF Specifications

The Bureau of Alcohol, Tobacco, Firearms and Explosives has established rules for marking guns. These rules help ensure that guns can be identified and tracked, which is important for following federal laws. Epilog’s marking machines can successfully meet gun marking requirements set forth by the ATF quickly and efficiently.

ATF Required Marks

- Manufacturer’s Name or Mark: The name or recognized abbreviation of the firearm’s manufacturer must be engraved or stamped on the firearm.

- Model: The model of the firearm must be marked on it.

- Caliber or Gauge: The caliber of the firearm (for rifles and handguns) or gauge (for shotguns) must be specified.

- Serial Number: Each firearm must have a unique serial number. You must locate this number in a place that is not easily altered or removed.