How Lasers Can Help Fight Counterfeiting

Counterfeiting is big business in the electronics world, manifesting itself through multiple avenues and a wide variety of methods. It is a threat pervasive to every part of the supply chain, from manufacturer to supplier to end user. It’s also a growing threat, according to a 2017 report published by the International Trademark Association (INTA) and the International Chamber of Commerce, which noted that the global economic value of counterfeiting and privacy could reach $2.3 trillion by the year 2022, along with an additional $1.9 trillion in terms of the wider social and economic impact costs.

There are ways to fight counterfeiting, of course, including comparing components to online databases, committing to use only known vendors and so on. But perhaps no anti-counterfeiting measure is more immediate and tangible than the engraving of genuine parts with unique and identifiable marks, like the ones you can achieve with an Epilog Laser system.

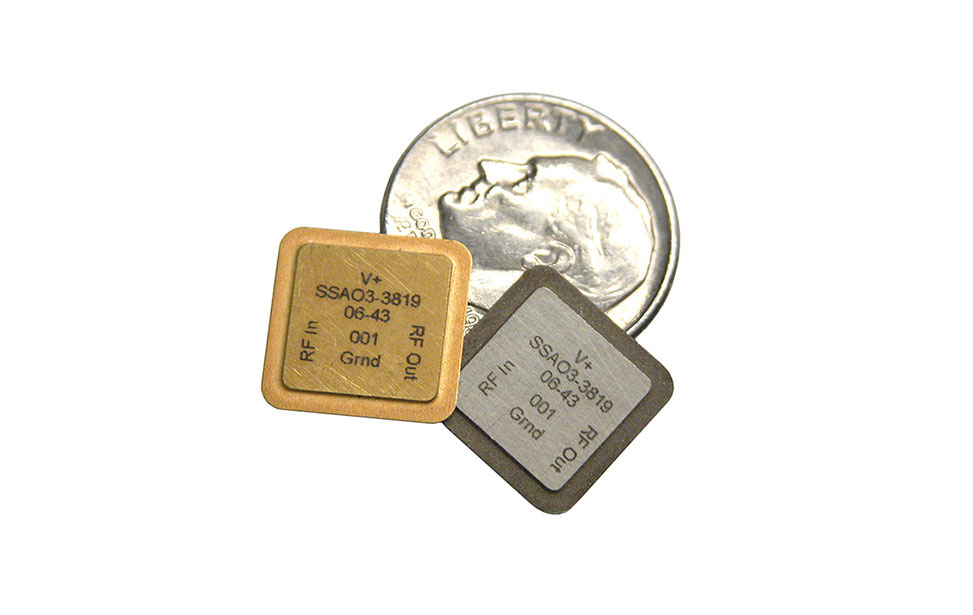

Indeed, one of the most valuable applications of laser engraving is the ability to permanently add a name, serial number, company logo or other identifying mark to just about any type of material imaginable – including many materials commonly used in electronics production. Thanks to the high resolution (up to 1,200 dpi) of Epilog’s engraving systems, high-quality marks can also be made within very small dimension parameters. It’s possible to mark everything from a corporate-supplied cellphone or laptop to PCB boards, silicon wafers and semiconductor parts.

In addition to customizable branding, Epilog systems also support unique identification (UID) codes in the form of bar codes, data matrix codes and human-readable text. These are required for identification, traceability and accountability of U.S. government property purchases, and can be applied directly either to an individual part or a non-removable tag affixed to an item. In the European Union, CE Markings are the standard indicator that a product meets essential requirements; mandated for a wide range of product families, including electronics, these too can be produced by an Epilog system.

Counterfeiting is an insidious problem in today’s manufacturing landscape, and no single tool can address all of its facets. But the introduction of a laser system at any stage in the supply chain can represent an elegant and cost-effective solution that will go a long way toward making possessions more secure, components more trustworthy and businesses more stable. Moreover, proper integration of the system represents an important step toward a safer, surer world.

For more information on using a laser machine to create identification marks, contact us to set up a demonstration with the distributor in your area.

Other News

Choosing the Best Laser Engraver for Wood Engraving Projects

Education: How to Pick the Best Laser Machine for Schools

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

How CO2 Laser Machines Can Increase Profits for Your Business

Laser Engraving Photos: Tips for Beginners

Have a story you want to see featured?

Press Contact for Epilog Laser:

Marketing Communications Specialist

About Epilog Laser

Since 1988, Epilog Laser has been designing and manufacturing flying-optics-based CO2 and fiber laser systems that can engrave and cut wood, acrylic, plastic, fabric, rubber and many other materials. Epilog specializes in developing laser systems that create unprecedented marking and cutting quality on all types of products. The company produces versatile and reliable systems that are affordable and easy to use.