Data Plates, ID Tags, & Name Plates

Durable, Precise, and Customizable Solutions for Every Industry

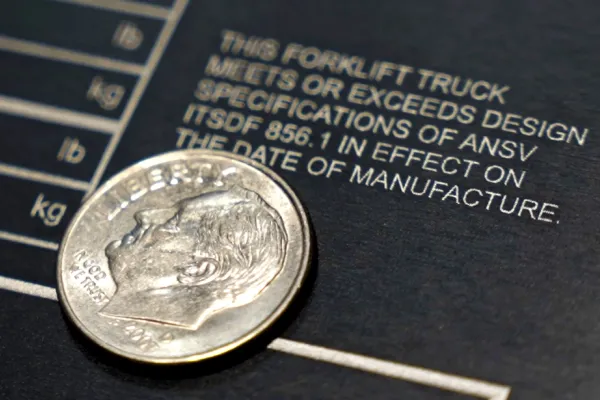

Engraved Identification

Made to Last

For manufacturers who need high quality marks on data plates, identification tags, custom nameplates, or other custom tags, laser engraving machines are an ideal solution. Unlike dot peen marking processes or screen printing, laser etching systems are faster and create a much cleaner mark on metal nameplates, asset tags, and much more.

Depending on the substrate, both CO2 laser and fiber laser systems can quickly and easily mark a wide range of materials that require serial numbers or other unique identification codes.

What types of identification marks can you achieve with a laser?

In nearly every industry identification requirements are becoming more stringent. Whether it’s for tracking, tracing, or quality assurance purposes, the demand for marking equipment continues to grow. Below are just a handful of the types of marks you can produce with an Epilog Laser machine:

| 2D Data Matrix Codes | Códigos de barras |

| Identification plates | Logos |

| Gravação de fotografias | Serial Numbers |

| Unique Identification (UID) | Graphic Images |

| Lot Codes | QR Codes |

What type of laser do you need to create unique identification marks?

Laser etching machines work on a wide variety of materials. CO2 laser systems are good for marking and cutting organic materials such as wood, acrylic, fabric, cork, rubber, etc. These types of lasers can mark metals like anodized aluminum, but bare metals will require pre-treatment with a metal marking agent prior to engraving.

Fiber lasers, on the other hand, are designed to mark metals and engineered plastics and require no pre-treatment prior to engraving. While they were not specifically created to leave colored marks, depending on the metal substrates, you can often mark color designs, depending on your speed, power, and frequency settings.

CO2 laser

- Acrylic plates

- Alumínio anodizado

- Plastic tags

Fiber Lasers

- ABS

- Stainless Steel Metal Tags

- Titânio

Benefits of Lasers over

Traditional Nameplate Marking Methods

Laser marking technology has been around for quite some time, however, until recently many manufacturers have used more traditional methods like dot peen marking or rotary engraving. Lasers offer a host of benefits over these more traditional methods including:

Non-contact Marking

With dot peen and rotary engraving there is part-to-part contact, which results in wear and tear on the marking tools and components. With a laser, there is no contact between parts. You simply insert your plate or tag and run the job. The structural integrity of the piece isn’t compromised as the laser does all the work!

Variety of Marks

Fiber lasers allow you to create a variety of marks on metals. Some of the most popular include annealed, etched, and polished looks. Traditional marking methods can provide depth but very little contrast, which can make barcodes and data matrix codes difficult to read.

Higher Quality Marks

Laser systems are capable of creating incredibly detailed marks even with fonts as low as 2.5. Traditional marking methods produce much more basic designs.

Engrave Multiple Parts at Once

Crie um modelo para colocar as peças e grave centenas de peças de uma só vez. Não é necessário um operador dedicado.

Engrave Large Items

Engrave barcodes even on your largest parts and tools – up to 48″ x 36″ x 12.25″ (1219 x 914 x 311 mm)

Mark Cylindrical Parts and Tools

We offer three Rotary Attachment options: a Rim-Style Rotary with quick setup for simple shapes, a 3-Jaw Chuck Rotary for precise etching, and a Rotary Attachment for our Galvo machine.

Porquê um epílogo?

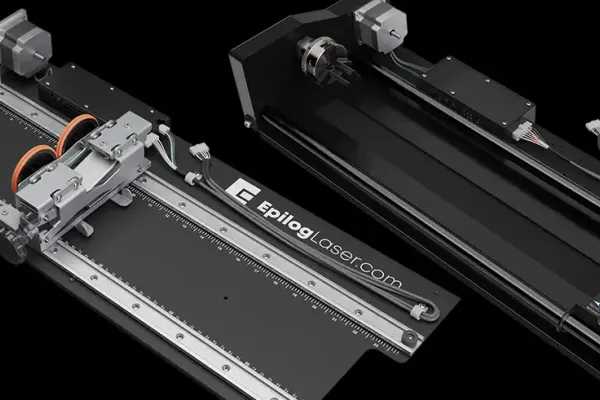

Epilog Laser offers a variety of solutions to help you meet your data plate, ID tag, and custom nameplate marking needs.

Depending on your substrate, one of our CO2 laser systems may be an ideal choice. If you are working with bare metal surfaces or engineered plastics, one of our fiber laser systems may be more suitable. And if you are marking a variety of both organic materials and metals, we also offer dual-option laser systems that include both fiber and CO2 laser sources.

Saber maisA variety of machines to fit your needs

- Six CO2 laser system options ranging in wattages from 30 to 120 and with table sizes from 16″ x 12″ (406 x 305 mm) up to 48″ x 36″ (1219 x 914 mm). These systems are capable of marking plastic, acrylic, wood, anodized aluminum, fabric/textiles, and more.

- Three fiber systems ranging from 24″ x 12″ (610 x 305 mm) to 48″ x 36″ (1219 x 914 mm) with wattage choices of 30 or 50. These systems were engineered specifically for bare metal marking and the marking of engineered plastics.

- With a variety of sizes and wattage configurations you can tackle your marking demands faster than ever before!

Marking plates with

variable data

Many times manufacturers need to mark a large batch of tags or plates with varying data, such as different serial numbers, names, or dates of manufacture. Epilog provides resources that allow you to quickly and easily set up files like this – check out this tutorial on creating serial tags with variable data!

What industries use lasers for ID marking applications?

-

Aerospace

Marking aircraft parts with permanent codes to meet FAA, DoD, AS9100, and other industry standards.

-

Automotive

Mark VIN numbers, serial numbers, and batch codes on engines, transmissions, and other critical components.

-

Produtos eletrónicos

Branding and labeling housings, chargers, batteries, and device components.

-

Fabrico

Serial numbers, part numbers, and lot codes for traceability throughout the supply chain.

-

Medical Devices

Engraving part numbers, lot codes, and manufacturer info that withstand repeated sterilization and cleaning.

-

Military

Permanent identification for tracking and logistics.

A gravação é fácil!

Imprima ao seu laser a partir de qualquer software gráfico

Configuração da obra de arte

Design no seu software favorito

Definições do material

Atribua a velocidade e potência consoante o material

Comece a Gravar!

Manda o trabalho ao laser e pressione vai!

O que é que se segue?

Whether you need tags custom engraved, stainless steel plates marked, or components serialized, Epilog has the right laser machine to fit your needs. Our applications lab would be happy to test your substrate on our systems and produce a detailed report on our recommended machine, wattage, and laser parameters to achieve the marks you are looking for. If you’re ready to see the lasers in action, contact us today to set up a demonstration!